Automation and Software Development

IEMA US

Mechatronic, Software and Artificial Intelligence solutions to

Unlock the full potential of your manufacturing capabilities

Services

Projects

Partners

Contact IEMA US

News

Presence – Innovation – Reliability

ABOUT US

IEMA US was founded in 2016 to deploy the multi-faceted competencies of IEMA Group over the North America region, supporting local customers and fostering the growth of innovative services

End-to-end capabilities on manufacturing engineering, providing integrated systems customized to your need: opportunity assessment, design, implementation and on-going technical assistance at your site.

mission

IEMA group’s competencies serving North America’s customers

VISION

Innovate manufacturing systems to sustainably boost productivity

RELIABLE

Our pledge on deadlines and resources availability assures your business continuity along execution

INNOVATIVE

A cluster of specialized companies contributing to project success with cutting edge solutions

PRESENT

Three teams of experienced engineers will address your calls in remote or activate intervention of our field force

High-Impact Services

Efficient, Sustainable, Intelligent : Your factory!

SCOPE

– mechanics

– mechatronics

– hardware (electric, electronic)

– software, data collection

– equipment logics, layout and ergonomics

fOCUS

can be on site, line, equipment or unitary operation, according to customer demand

SERVICE

benefits of specialized competencies available within IEMA group, making use of ad-hoc methodology and tools

A structured diagnose of your manufacturing system, allowing opportunity assessment and budget planning

A sustainable approach to lifecycle management of your assets

upgrade

an alternative to replacement of assets nearing end of life, offering the customer:

– faster timeline

– lower impact on GMP procedures and operator training

– quantifiable reduction of CO2 emission for the project

– substantially lower investment

global solutions

multi-disciplinary approach to problem solving will optimize:

– cycle time

– line reliability

– defect rate

improvemeNts

opportunity is quantified by IEMA ahead of project sign-off, allowing a «IEMA or Buy» evaluation

data analysis

Iemacle system processes a wide set of equipment data through a proprietary software based on AI, trained to recognize early-stage signals of projected failure

focus

besides ad-hoc alarms, Iemacle generates periodic reports, keeping maintenance staff always aware of what’s next, this allows schedules and it turns repair downtime into operational availability

data customization

Customized data collection system +

Standardized user interface =

A versatile and adaptable tool,

scalable to factory or corporate level

Tomorrow’s failures fixed today: AI capabilities to the service of productivity

High-Impact Services

Efficient, Sustainable, Intelligent : Your factory!

A structured diagnose of your manufacturing system, allowing opportunity assessment and budget planning.

scope

– mechanics

– mechatronics

– hardware (electric, electronic)

– software, data collection

– equipment logics, layout and ergonomics

focus

can be on site, line, equipment or unitary operation, according to customer demand.

service

benefits of specialized competencies available within IEMA group, making use of ad-hoc methodology and tools.

A sustainable approach to lifecycle management of your assets.

upgrade

an alternative to replacement of assets nearing end of life, offering the customer:

– faster timeline

– lower impact on GMP procedures and operator training

– quantifiable reduction of CO2 emission for the project

– substantially lower investment

global solutions

multi-disciplinary approach to problem solving will optimize:

– cycle

– time

– line reliability

– defect rate

improvements

opportunity is quantified by IEMA ahead of project sign-off, allowing a «IEMA or Buy» evaluation.

Tomorrow’s failures fixed today: AI capabilities to the service of productivity.

data analysis

Iemacle system processes a wide set of equipment data through a proprietary software based on AI, trained to recognize early-stage signals of projected failure.

predictive maintenance

besides ad-hoc alarms, Iemacle generates periodic reports, keeping maintenance staff always aware of what’s next, this allows schedules and it turns repair downtime into operational availability.

data customization

Customized data collection system

+

Standardized user interface

=

___________

A versatile and adaptable tool, scalable to factory or corporate level.

Core Services

Automation

System Integration

Software Development

We Simplify What Is Complex

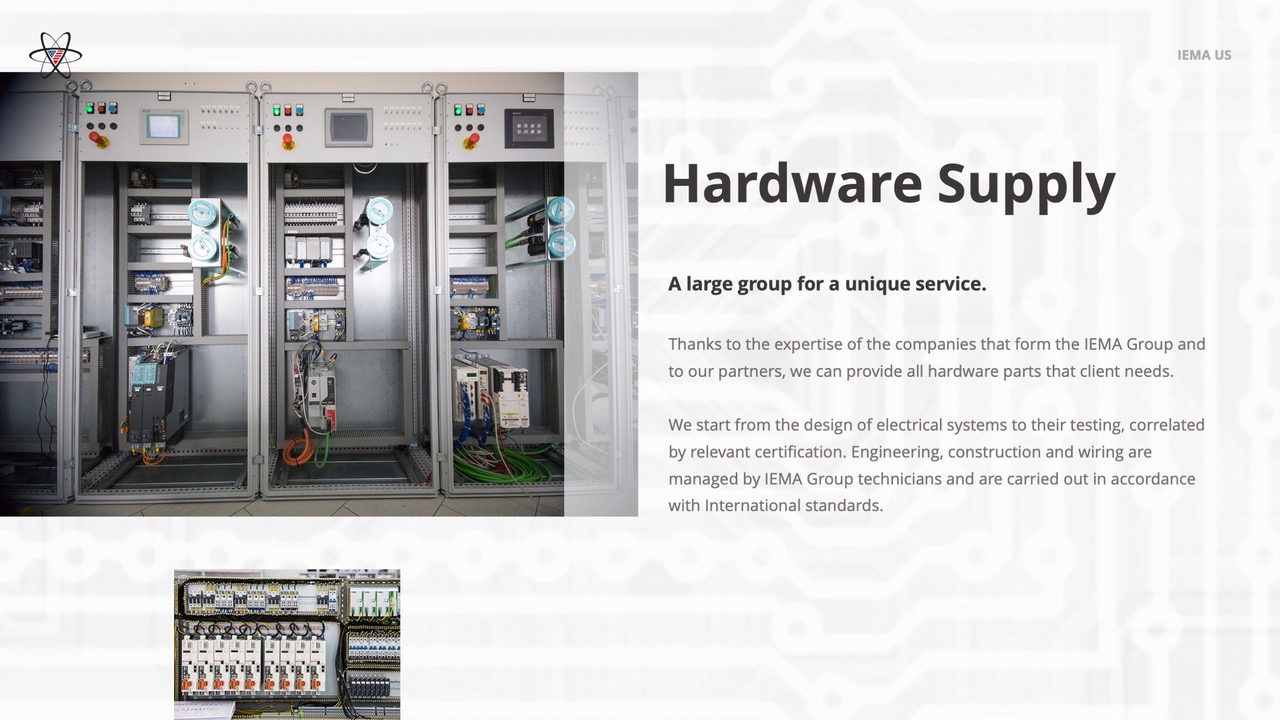

Hardware Supply

Robotics & Mechanical Installation

24/7 Remote Assistance

Specialty Services

System Certification

Technical Documentation & Translation

We’ll build a package of technical documentation as per applicable standards and regulations. Translation services facilitate equipment certification and regulatory compliance

Interactive Training

Discover Iema US Interactive Training, where learning meets engagement for an immersive educational experience

Project Analysis

Unlock the potential of your projects with meticolous Analysis, paving the way for success and informed decision-making

Projects

Partners

Software Development

Robotics and Mechanical Installation

Phone Number

Business Hours

Mon – Fri : 09–12:30 / 13:30–17

Sat – Sun : Closed